After what seems like decades of manufacturing jobs moving outside of the United States, thousands were added in April due in part to increases in supply chain management and China’s closed shipping ports from the coronavirus pandemic, according to experts.

The manufacturing industry added 55,000 jobs throughout the United States, which offers journalists the opportunity to look at what some experts say is an employment trend that affects various neighborhoods.

Arizona is an example of a blooming manufacturing hub

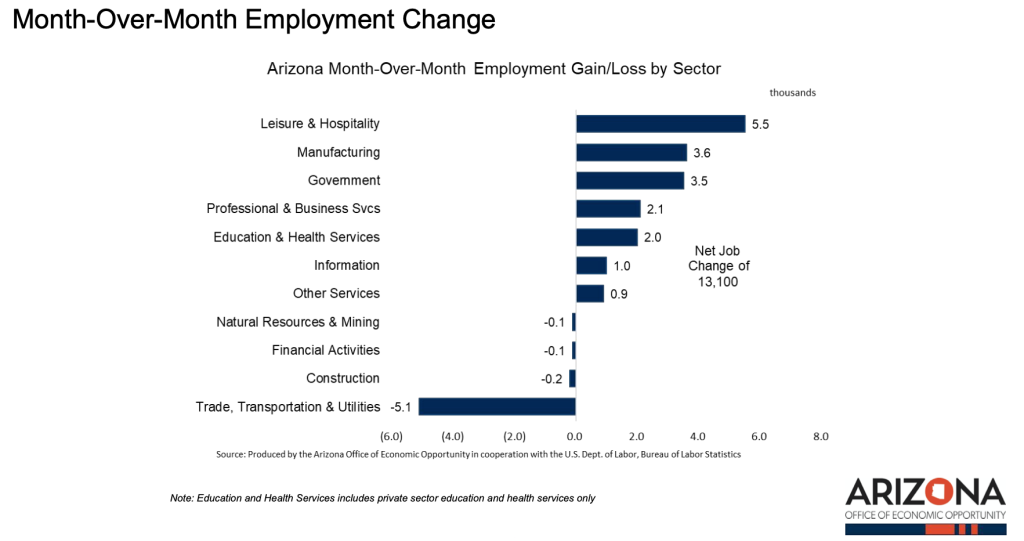

In Arizona, for example, nearly 4,000 manufacturing jobs were added to the state’s job market in April, according to the state’s monthly employment report.

It’s a trend, Phoenix Deputy City Manager Alan Stephenson said, that will benefit residents.

“The increase in manufacturing jobs … provides quality jobs for our residents, goods/services desired by our residents and helps build infrastructure like streets and water lines,” he said.

Arizona’s 3.6% increase in manufacturing jobs shines a light on what is going on in a growing industry – an industry that has not dominated since the late 1970s. Intel, Honeywell International, Raytheon, Boeing and Microchip Technology already call the state home.

Their presence and others have helped rank the state No. 2 in reshoring – a practice of bringing overseas manufacturing businesses back to the United States. Arizona trails behind Ohio on the Reshoring Initiative’s 2001 list. The Reshoring Initiative is a nonprofit organization with a mission to bring more manufacturing jobs to the United States. Other states that rank on the company’s list of places that have been a part of a 38% increase in reshoring in 2021 include Tennessee, Oklahoma, California, Georgia and North Carolina.

Not only is the state of Arizona highlighted as an industry up and comer, Phoenix is also ranked No. 7 on the top 10 manufacturing cities in the United States by IndustrySelect — a data provider that profiles industrial businesses.

“It is not a fluke,” that Arizona is ranked No. 2 in the Reshoring Initiative’s report and has received thousands of manufacturing jobs in April, said Hitendra Chaturvedi, a professor at Arizona State University’s W. P. Carey School of Business.

Chaturvedi, a supply chain management expert, believes the country should focus more on maintaining and building upon the manufacturing jobs that have been acquired. Some of those jobs have come to the United States because of China’s shipping closures due to COVID-19.

In his opinion article called “Who Moved My Wall,” Chaturvedi said that as the global pandemic continues, businesses that relied on China have been “at a standstill” or “dead in the water.”

“All of our eggs were in China’s basket,” Chaturvedi added.

To ensure those eggs don’t remain in China’s basket, Chaturvedi believes businesses in North America and Europe should plan to “create a viable regional alternative to China’s manufacturing monopoly to hedge risk for any future catastrophic event like a pandemic,” according to his article.

Looking at the whole ecosystem

While China prepares to open its ports and states like Arizona are enjoying manufacturing increases, the United States should establish a mitigation plan to better support and build upon manufacturing companies in the country, Chaturvedi said.

That support could be considered necessary for one of the world’s 10 most valuable companies with a market value of over $550 billion: The Taiwan Semiconductor Manufacturing Company or TSMC. TSMC has built a $12 billion fabrication plant in Phoenix, according to CNBC, but it has not come to the area alone.

“Large companies are just the tip of the iceberg,” Chaturvedi said. “The entire ecosystem comes with it. In the ecosystem, (the large companies) are the ones that get noticed.”

But they are joined by small and medium-sized companies that will also support hiring in the area, Chaturvedi said.

“This is what we’re seeing at the university,” Chaturvedi added. “Students are getting hired across the board.”

Problems that come along with additional jobs

The availability of more manufacturing jobs has led to another problem within the industry: a lack of skilled labor. According to The Manufacturing Institute and Deloitte, the United States could see a manufacturing skills gap of 2.1 million unfilled jobs by 2030. The report says the cost of those missing jobs could total $1 trillion in 2030 alone.

“Given the foundational role the manufacturing sector plays in our nation’s economy, it is deeply concerning that at a time when jobs are in such high demand nationwide, the number of vacant entry-level manufacturing positions continues to grow,” said Deloitte Vice Chairman Paul Wellener by news release. “Attracting and retaining diverse talent presents both a challenge and solution to bridging the talent gap. To attract a new generation of workers, the industry should work together to change the perception of work in manufacturing and expand and diversify its talent pipeline.”

For those believing America has been able to greatly increase its supply chain due to China’s closed ports, Chaturvedi says it’s much too early to make those kinds of assertions.

“There are too many slips between the cup and the lip,” Chaturvedi said in illustrating the steps America needs to take to be a dominator in the supply chain.